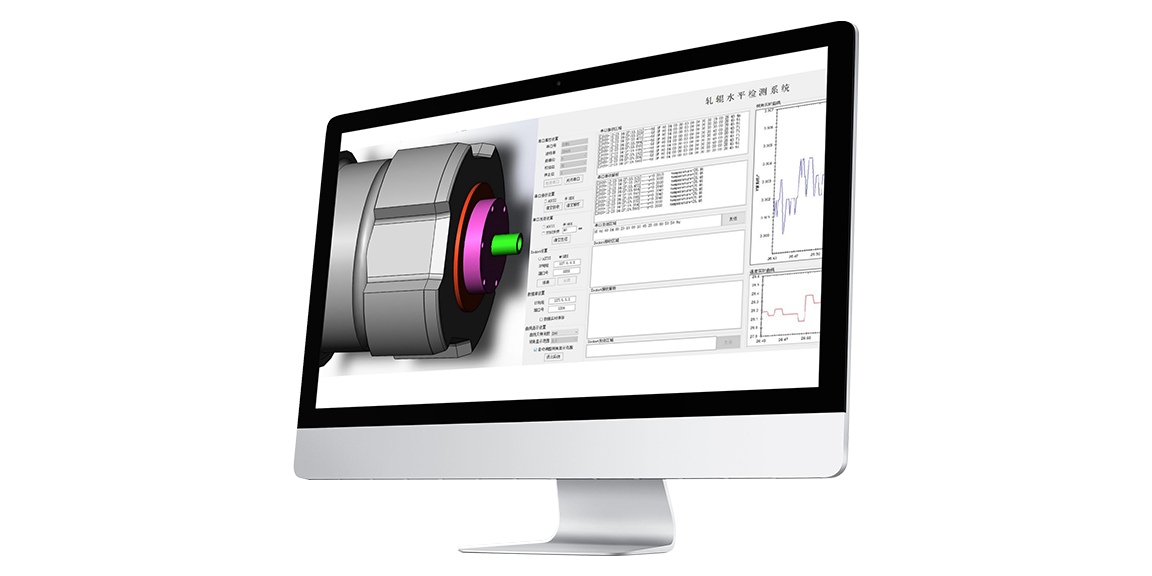

On line automatic measuring device for roll level

Function description: The horizontal height difference on the sides of rolling mill drive side and operating side has always been the concern of steel rolling process. However, the physical measurement of the level of the lower roll surface can only be carried out when the machine stops, and the efficiency is low. Once the abnormality of the difference between the two AGC cylinders on both sides occurs during the roll replacement,it is difficult to immediately distinguish whether the level problem is caused by the lower roll system mechanism or the upper one . The product is installed on the lower support roller end, which can realize online measurement of actual value of the lower support roller surface level. It will play a good role in controlling the roller system level of the manufacturer in time, guiding the operation and adjustment, improving the rolling stability of the mill, improving the quality of the product, and reducing the loss of key equipment (such as the damage of AGC cylinder biased load). Product description: The principle of this product is to accurately detect the angle between the axis of the support roller and the physical horizontal line through a special inclination sensor device, so as to obtain the physical level difference between the roller surfaces on both sides of the support roller. The installation part of the product is on the end face of the support roller, and the outline structure is shown in the figure.

湘公網(wǎng)安備43060402000026號(hào) 湘ICP備16013601號(hào)-1

湘公網(wǎng)安備43060402000026號(hào) 湘ICP備16013601號(hào)-1